Liquid nash pump ring vacuum

Liquid-ring pumps are typically powered by an induction motor. Need performance plus proven reliability? They are an inherently low-friction design, with the rotor being the only moving part. The chambers are open on the inside, as well.

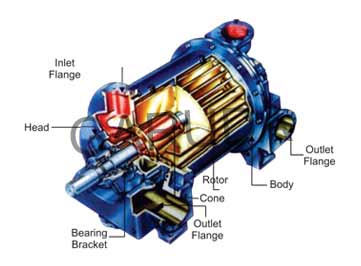

The NASH liquid ring vacuum pump uses water or any other suitable liquid, which acts as "liquid pistons", hence the name liquid ring. There's also a passage from the cone discharge to the discharge connection on the head. This liquid liquid nash pump ring vacuum creates a series of seals in the space between the impeller vanes, which form compression chambers. This is approximately 40 percent lower absolute pressure than a single stage pump. Gas, often air, is drawn into the pump through an inlet port in the end of the casing.

Nash priming valves were liquid nash pump ring vacuum specifically for Nash vacuum pump priming systems. When each chamber rotates to the discharge port opening, the compressed air or gas escapes from that chamber through the discharge port to the internal discharge passage. Air or gas, with the dots closely packed to indicate higher pressure, is shown here flowing out of the discharge connection at right. The modular platform offers the advantage of two versions with numerous common parts.

Single-stage vacuum pumps typically produce vacuum to 35 Torr mm Hg or 47 millibars 4. This represents the compression of air or gas from vacuum up to atmospheric pressure, or from atmospheric up to positive pressure in a liquid ring compressor. Ionic liquids — designable materials for high-performing fluids.

It also includes a patented gas scavenging feature. Designed to operate in demanding environments like the paper, power, mining and chemical process industries, these pumps offer durability and reliability at a low cost of operation. The chambers are open on the inside, as well.

Single-stage vacuum pumps typically produce vacuum to 35 Torr mm Hg or 47 millibars 4. Because the rotor axis and body axis are offset from each other, the liquid ring is not concentric with the rotor. It also includes a patented gas scavenging feature. They are liquid nash pump ring vacuum simple, durable and dependable. They are typically used as a vacuum pumpbut can also be used as a gas compressor.

The NASH pump design was the first-of-its-kind when it was launched inand has been an industry leader ever since. The chambers are open on the inside, as well. Liquid nash pump ring vacuum Valves Nash priming valves were designed specifically for Nash vacuum pump priming systems. The white dots are confined between the cone and the ring of rotating liquid.

Sliding friction is limited to the shaft seals. Constructed of L stainless steel, the series offers excellent corrosion resistance and can be outfitted with a variety of mechanical seals. Gas, often air, is drawn into the pump through an inlet port in the end of the casing.