Liquid ring vacum pump

With a broad range of suction volume, vacuum and discharge pressure, pumps in this series are used in almost all industrial applications.

Offering higher vacuum capabilities with improved efficiency, the NASH 2BE5 serves a wide range of industrial applications.

Capacity to cfm, Vacuum to 1" Hg abs, Compressor Pressure to 5. Using a magnetic drive to achieve non-contact torque transmission, the 2BM Series offers leak free performance and is hermetically sealed.

Capacity to cfm, Vacuum to 1" Hg abs, Compressor pressure to Nash priming valves were designed specifically for Nash vacuum pump priming systems. They are extremely simple, durable and dependable. Shaft bearings on heavy cast iron brackets are easily accessible for servicing. The top connection of the pump is the inlet, while the side connection is its discharge some NASH pumps do have a different orientation.

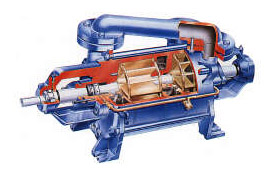

The NASH liquid ring vacuum pump uses water or any other suitable liquid, which acts as "liquid pistons", hence the name liquid ring. It's apparent that the chambers between the rotor blades, shown here in yellow, are open around the periphery.

The chambers are open on the inside, as well. These inner edges of the rotor blades are machined to rotate around the cone surface, shown in red , with a close non-contact fit. An internal passage joins the openings from the pump inlet to an inlet port in the cone. There's also a passage from the cone discharge to the discharge connection on the head. Some NASH pumps have a port plate configuration rather than conical, but the principle is the same. In some systems, the discharged ring-liquid is cooled by a heat exchanger or cooling tower , then returned to the pump casing.

In some recirculating systems, contaminants from the gas become trapped in the ring-liquid, depending on system configuration.

These contaminants become concentrated as the liquid continues to recirculate, eventually causes damage and reduced life to the pump. In this case, filtration systems are required to ensure that contamination is kept to acceptable levels.

In non-recirculating systems, the discharged hot liquid usually water is treated as a waste stream. In this case fresh cool water is used to make up the loss. Environmental considerations are making such "once-through" systems increasingly rare. These simple, but highly reliable pumps have a variety of industrial applications.

They are used to maintain condenser vacuum on large steam-turbine generator sets by removing incondensable gasses, where vacuum levels are typically 30—50 mbar. They are used on paper machines to dewater the pulp slurry and to extract water from press felts.

Another application is the vacuum forming of molded paper-pulp products egg cartons and other packaging. Other applications include soil remediation, where contaminated ground water is drawn from wells by vacuum. In petroleum refining, vacuum distillation also makes use of liquid-ring vacuum pumps to provide the process vacuum. Liquid-ring compressors are often used in vapor recovery systems. Liquid-ring vacuum pumps can use any liquid compatible with the process, provided it has the appropriate vapor pressure properties, as the sealant liquid.

Although the most common sealant is water, almost any liquid can be used. The second most common is oil. Since oil has a very low vapor pressure, oil-sealed liquid-ring vacuum pumps are typically air-cooled.