Static electricity pump liquid

Toluol, an example of such liquid, has a long history of causing fires. If the conductivity cannot be raised to the recommended value, the vessel should be inserted. Pebble mills present static electricity pump liquid additional hazard because their porcelain lining is an insulator that will prevent the flow of static charges from liquid to ground, even if the mill is grounded. It should be noted that the static accumulation in liquids cannot be controlled by raising the ambient humidity. In bulk-filling operations the velocity of the incoming liquid should not exceed 3 feet per second until the pipeoutlet is covered; the velocity static electricity pump liquid then be increased to the 15 feet per second maximum mentioned previously.

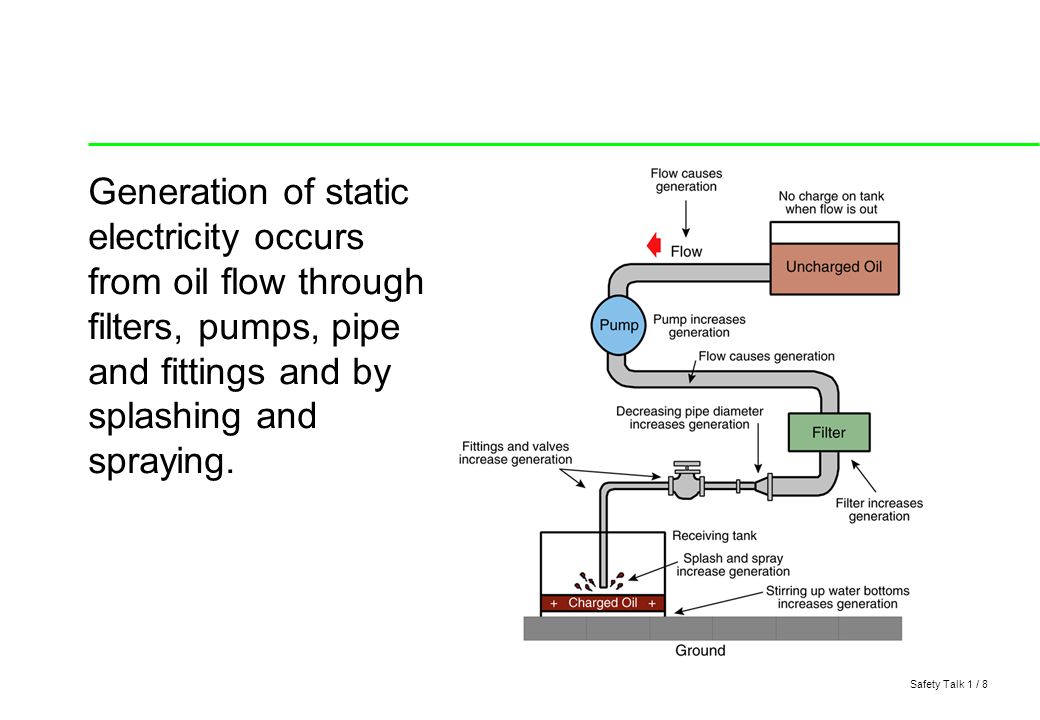

Some flammable liquids have very low conductivities and tend to accumulate static charges. Introduction Static electricity is a major cause of fires and explosions in many industries. The most common generators of static electricity are processes involving flammable liquids.

Piping Systems - The most effective method of reducing the accumulation of static charges in piping systems is through proper pipe sizing to keep liquid velocities low. Introduction Static static electricity pump liquid is a major cause of fires and explosions in many industries. A recommended maximum velocity in piping systems is 15 feet per second.

The rate of charge dissipation on most solid surfaces can be increased by raising the humidity. Introduction Static electricity is a major cause of fires and explosions in many industries. Static electricity is generated by liquids flowing through pipes, and in mixing, static electricity pump liquid, pumping, filtering, or agitating liquids. Tests should be run to ensure that the conductivity additive does not cause formulation problems. If the conductivity cannot be raised to the recommended value, the vessel should be inserted.

The rate of charge dissipation on most solid surfaces can be increased by raising the humidity. Occasionally, such methods cannot be applied, and the use of inert gas in vapor spaces must be considered. This hazard is best controlled by static electricity pump liquid the mill. The required relaxation time depends upon the conductivity, the liquid velocity, and the type of filter. Introduction Static electricity is a major cause of fires and explosions in many industries.

Typically, only a few parts per million of the additive are required. Toluol, an example of such liquid, has a long history of causing fires. Static electricity is a major cause of fires and explosions in many industries.

This hazard is best controlled by inserting the mill. The most common generators of static electricity pump liquid electricity are processes involving flammable liquids. Typically, only a few parts per million of the additive are required. Tests should be run to ensure that the conductivity additive does not cause formulation problems.

The most common generators of static electricity are processes involving flammable liquids. Polar solvents are more conductive than non-polar solvents. For example, the 30 second relaxation time may not be necessary with a conductive liquid.

The additive may not be suitable for use in coatings for food containers. Tests should be run to ensure that the conductivity additive does not cause formulation problems. In bulk-filling operations the velocity of the incoming liquid should not exceed 3 feet per second until the pipeoutlet is covered; the velocity may then be increased to the 15 feet per second maximum mentioned previously. If possible, polar solvents should be added before non-polar solvents or particulates static electricity pump liquid added.

A recommended maximum velocity in piping systems is 15 feet per second. For example, the 30 second relaxation time may not be necessary with a conductive liquid. In some instances, proprietary anti-static agents, developed for use with fuels, can be used as additives to reduce the charge accumulation. Static electricity pump liquid solvents are more conductive than non-polar solvents. The rate of generation is influenced by the conductive of the liquids, the amount of turbulence in the liquid, the interfacial surface area between the liquids and other surfaces, liquid velocity, and the presence of impurities.